How to choose the vacuum system of CNC engraving machine?

Vacuum suction devices occupy an important position in the CNC engraving machine industry, especially in the woodworking advertising engraving industry. With such a set of vacuum suction devices, the whole working environment is clean and tidy! Without this set, it feels like eating soil all day...

Vacuum suction devices occupy an important position in the CNC engraving machine industry, especially in the woodworking advertising engraving industry. With such a set of vacuum suction devices, the whole working environment is clean and tidy! Without this set, it feels like eating soil, wood chips, and powder all day... so how do we choose a practical and efficient vacuum system.

CNC engraving machine vacuum cleaner should have the following advantages:

(1) Good mobility and arbitrariness;

(2) Good vacuum suction effect; Pure copper motor;

(3) Surface spray treatment; thickened iron sheet;

(4) Scratch resistance and corrosion resistance;

(5) Longer service life.

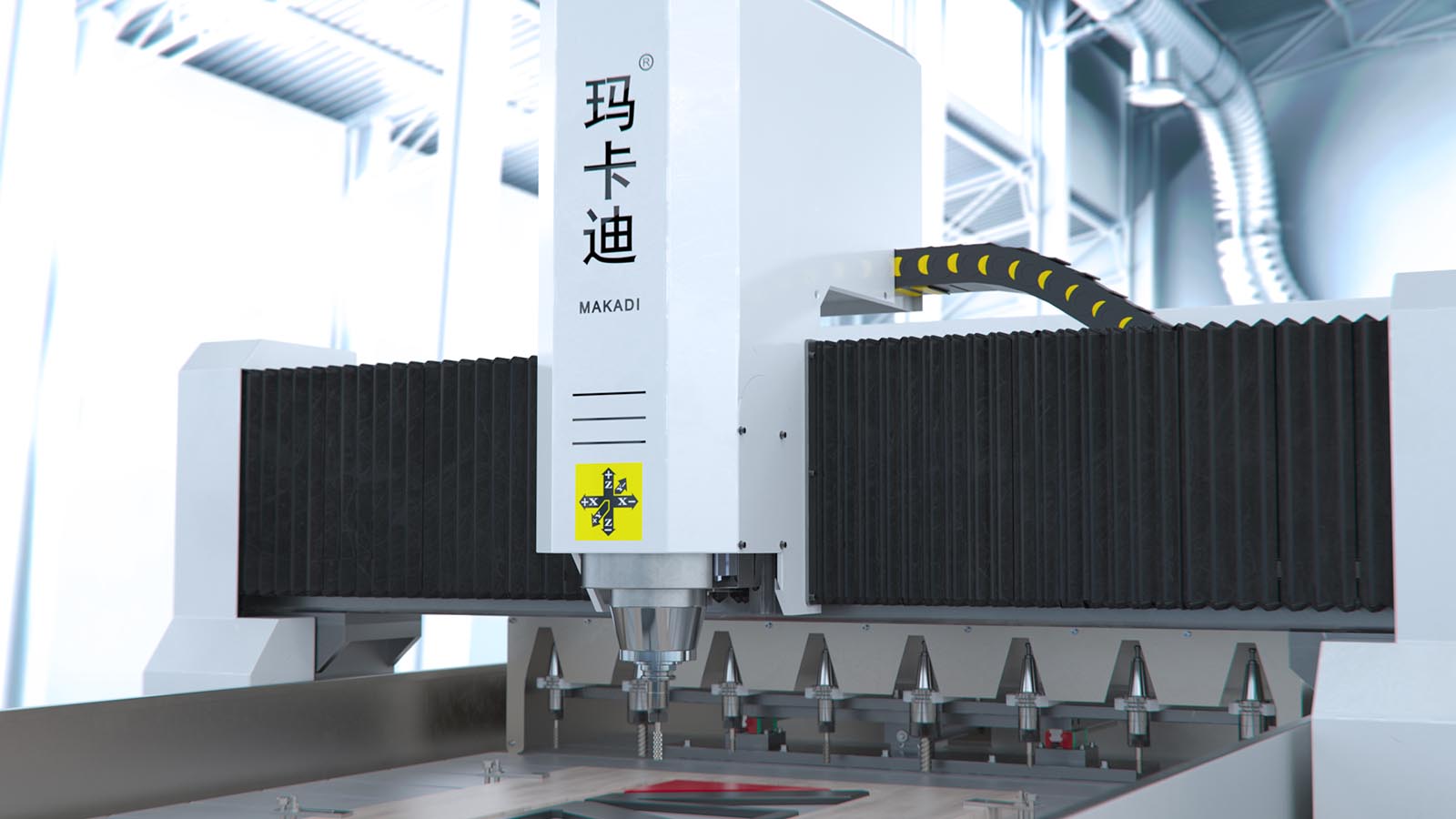

The advantages that CNC engraving machine vacuum hood should have:

(1) Push-pull type, suitable for different models of machines, more convenient to change tools; At the same time, the engraving machine of three processes and four processes can be used as well!

(2) Detachable aluminum brush, encryption thickened, no hair loss, screw fixing is stronger;

(3) The front end elevation design leaves space for the pressure wheel, which is specially used for the pressure wheel engraving machine;

(4) The thickened steel plate does not deform, good quality, visible;

(5) Surface paint treatment, anti-rust, beautiful

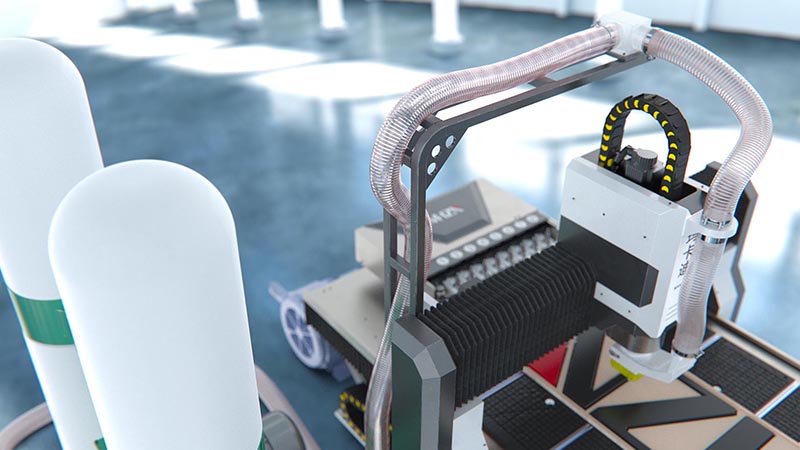

Industrial vacuum cleaner hoses are mainly used in supporting the entire vacuum system, such as some carpentry, furniture and other carving manufacturers woodworking machinery used the most. PU hose is used as an industrial vacuum cleaner hose, mainly used in abrasive solids such as dust, powder, fiber, chips and particles, gas and liquid environments, for dust removal and suction plant, paper and textile fiber suction conveying.

I hope our article can help you, if it helps you, please like us, if it does not help you, please spit and forward! Thank you here!