What are the differences between CNC cutting machine and CNC engraving machine?

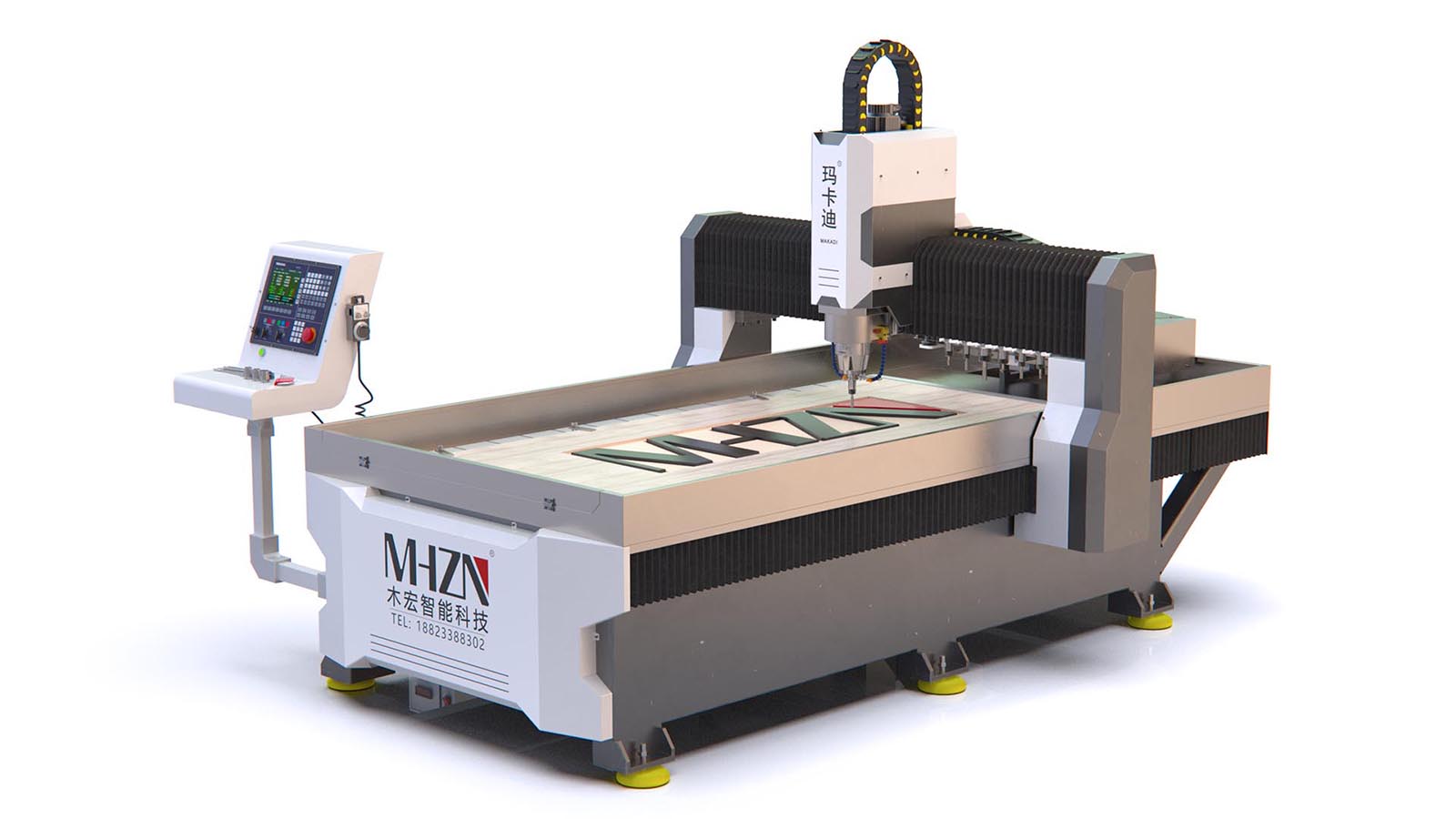

CNC engraving machine is intelligent engraving equipment, CNC cutting machine is intelligent plate furniture cutting equipment...

engraving equipment, CNC cutting machine is intelligent plate furniture cutting equipment.

CNC cutting machine and CNC engraving machine have overlapping parts in function, cutting machine is mainly used for plate furniture cutting, punching, grooving, milling, engraving and other functions, while the engravingmachine is mainly used for plate or three-dimensional parts relief, hollow carving, three-dimensional engraving and other functions.

In addition, from the price point of view, the price of the cutting machine is much higher than the CNC engraving machine, and the factors affecting the price are mainly reflected in the different configuration and control system.

The configuration of the engraving machine is generally an ordinary stuffy bed, the guide rail slider is generally 25 models, most of the table structure is aluminum alloy plus soft PVC, most of the drive motors are domestic stepper motors, and the rack is also a rack with a relatively small modulus of 1.25 purposes

The combination of these configurations is that the running speed is slow, and the long-term heavy load operation will lead to inaccurate step loss accuracy, and even affect the service life of the machine.

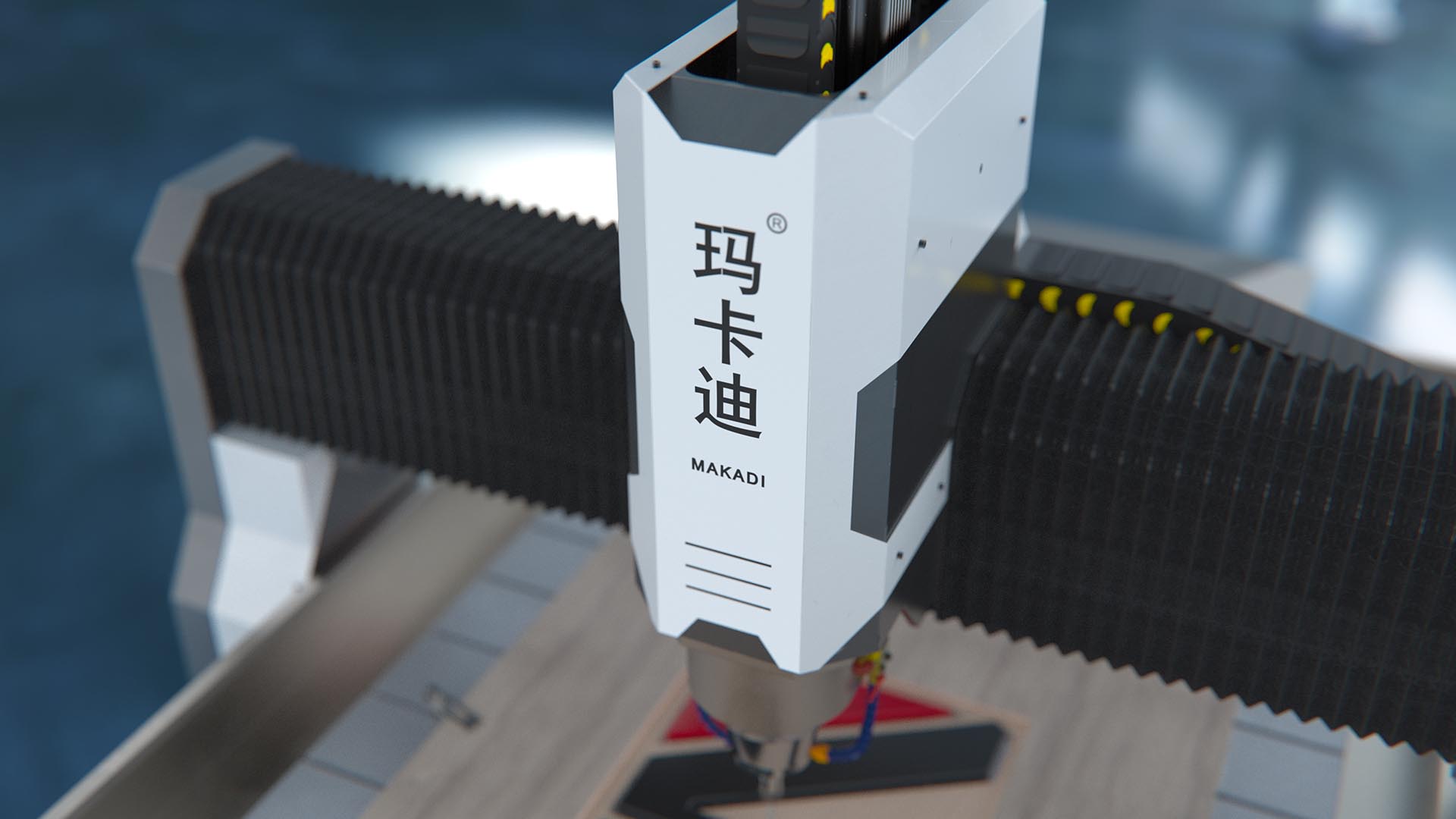

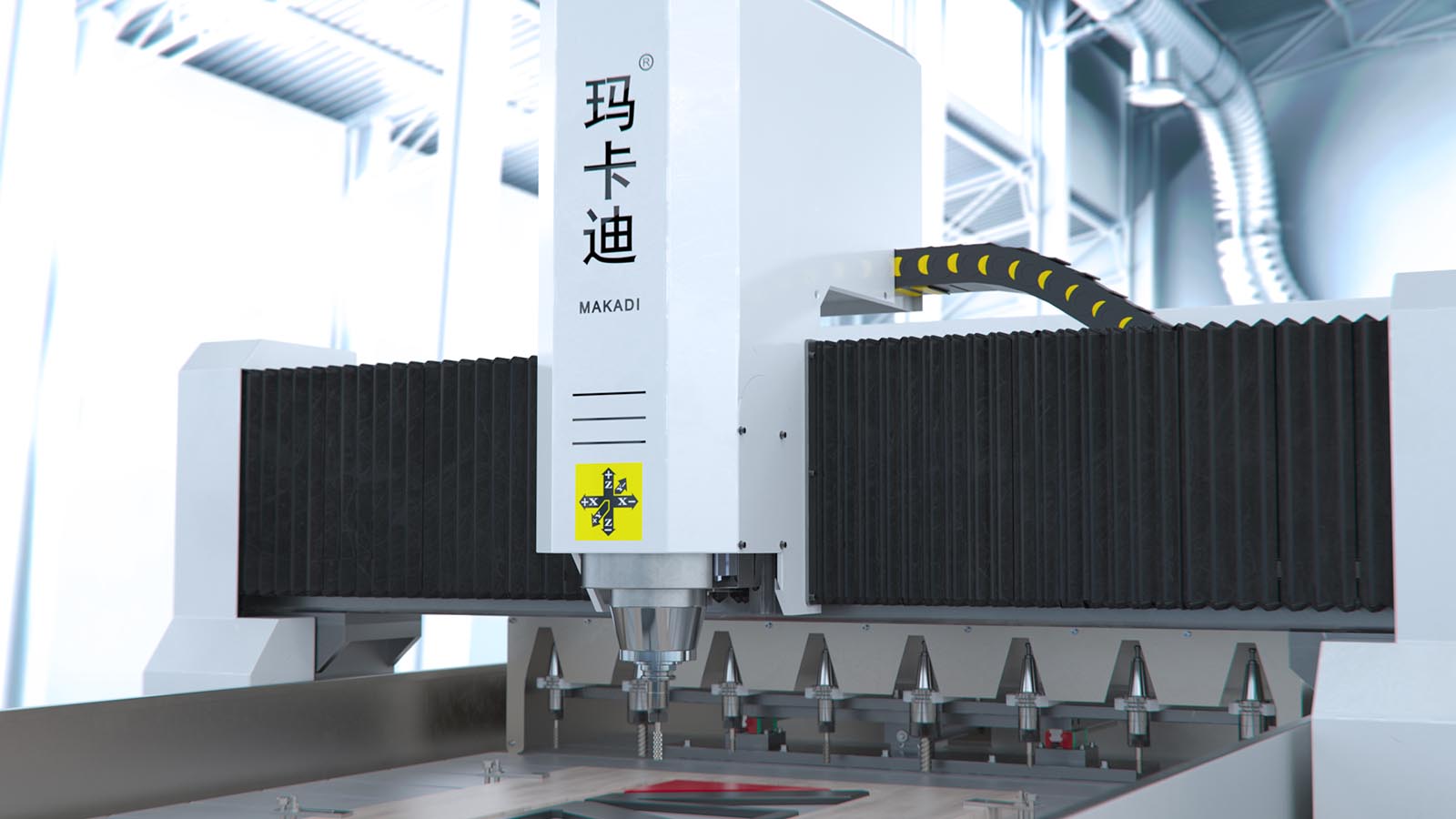

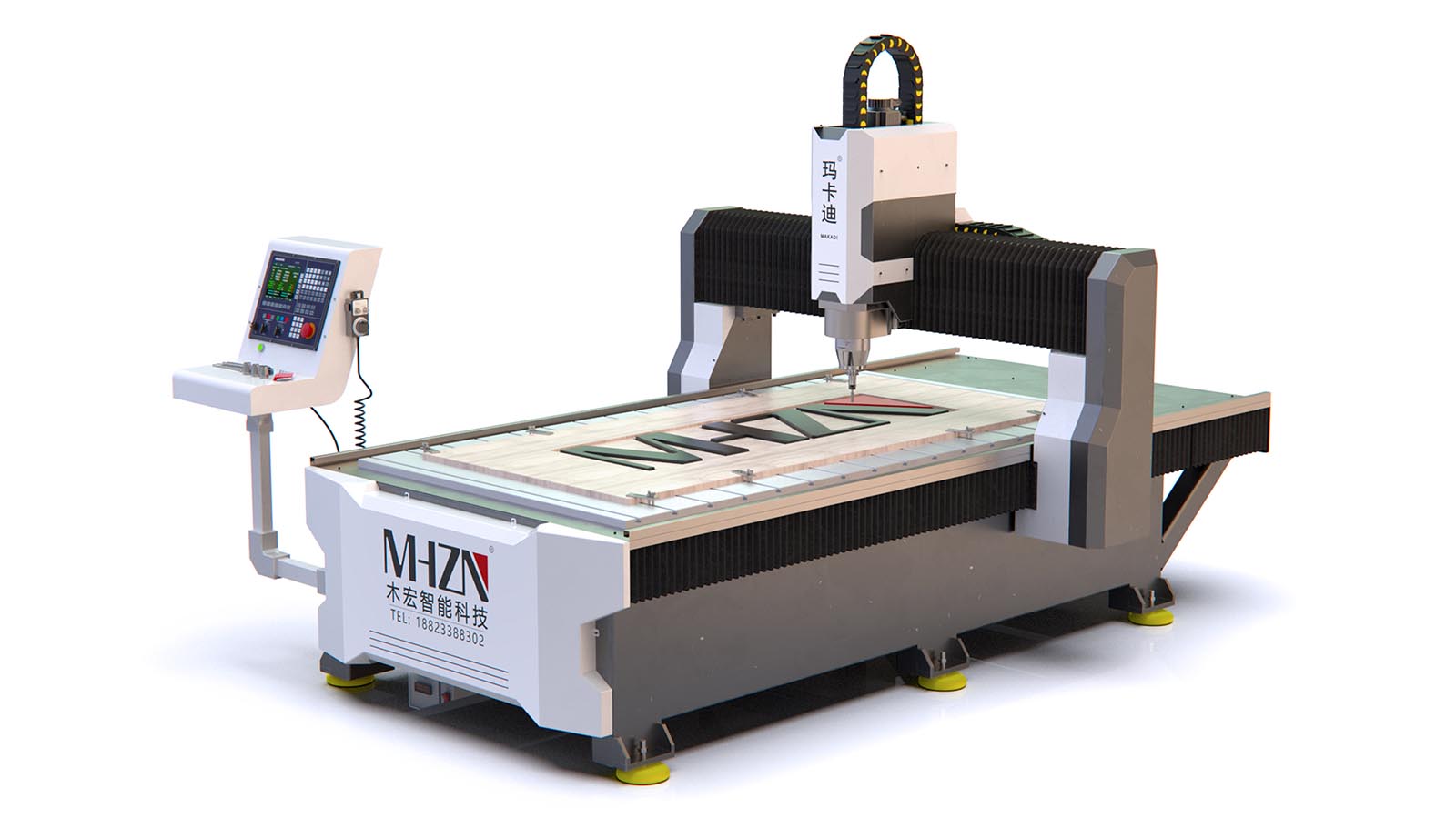

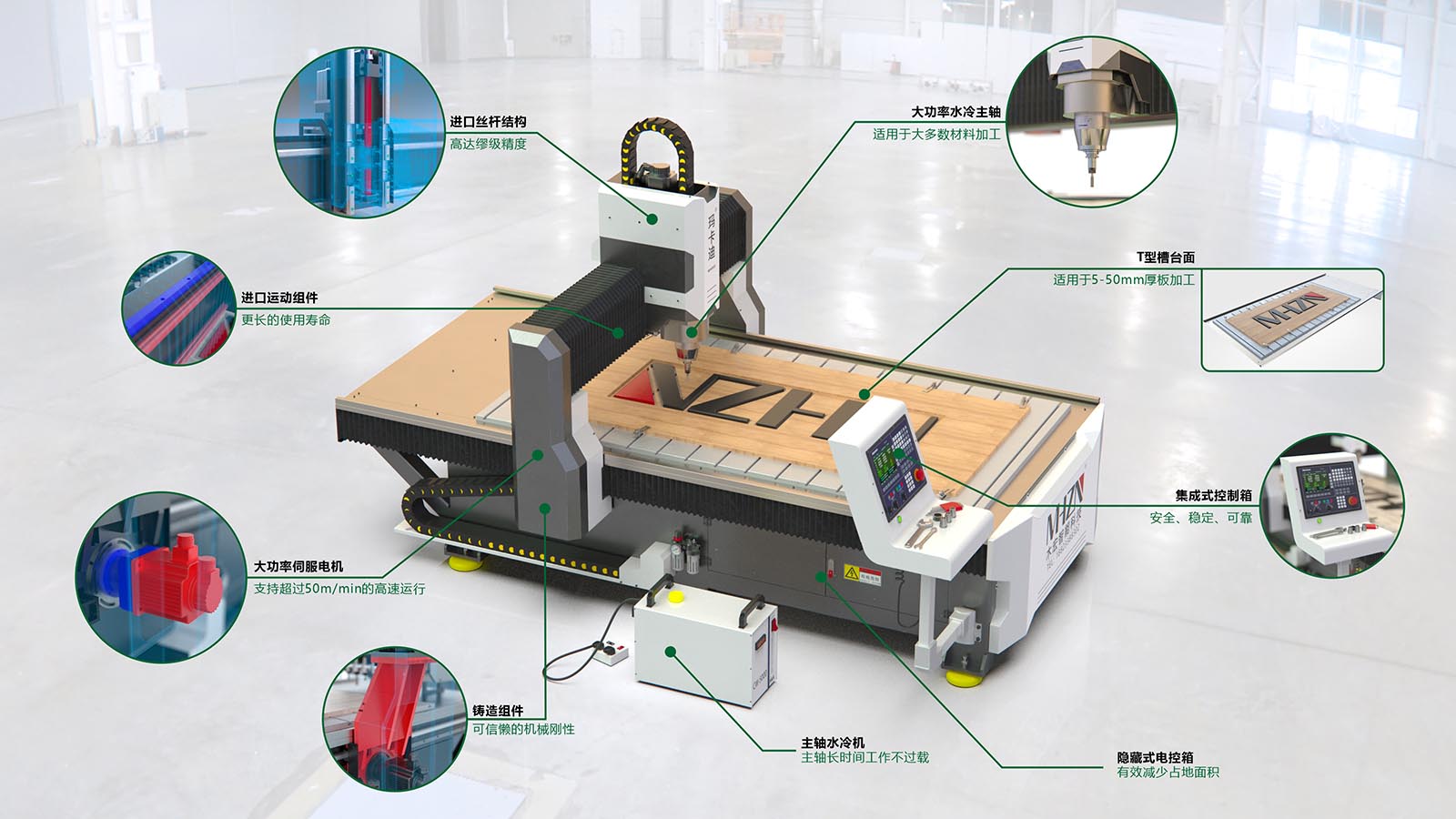

Most of thecurrent configuration of the cutting machine is double-weighted five-sided milling machine, the stability and firmness performance are much improved compared to the engraving machine, and the overall weight is twice or even more than twice the weight of the engraving machine tool

Most of the tablestructure is hard fireproof PVC vacuum adsorption table, in order to meet the high-precision, heavy-duty work of plate cutting, most of them choose 25 or 30 models of square rail sliders, and XY axial direction are equipped with reducers

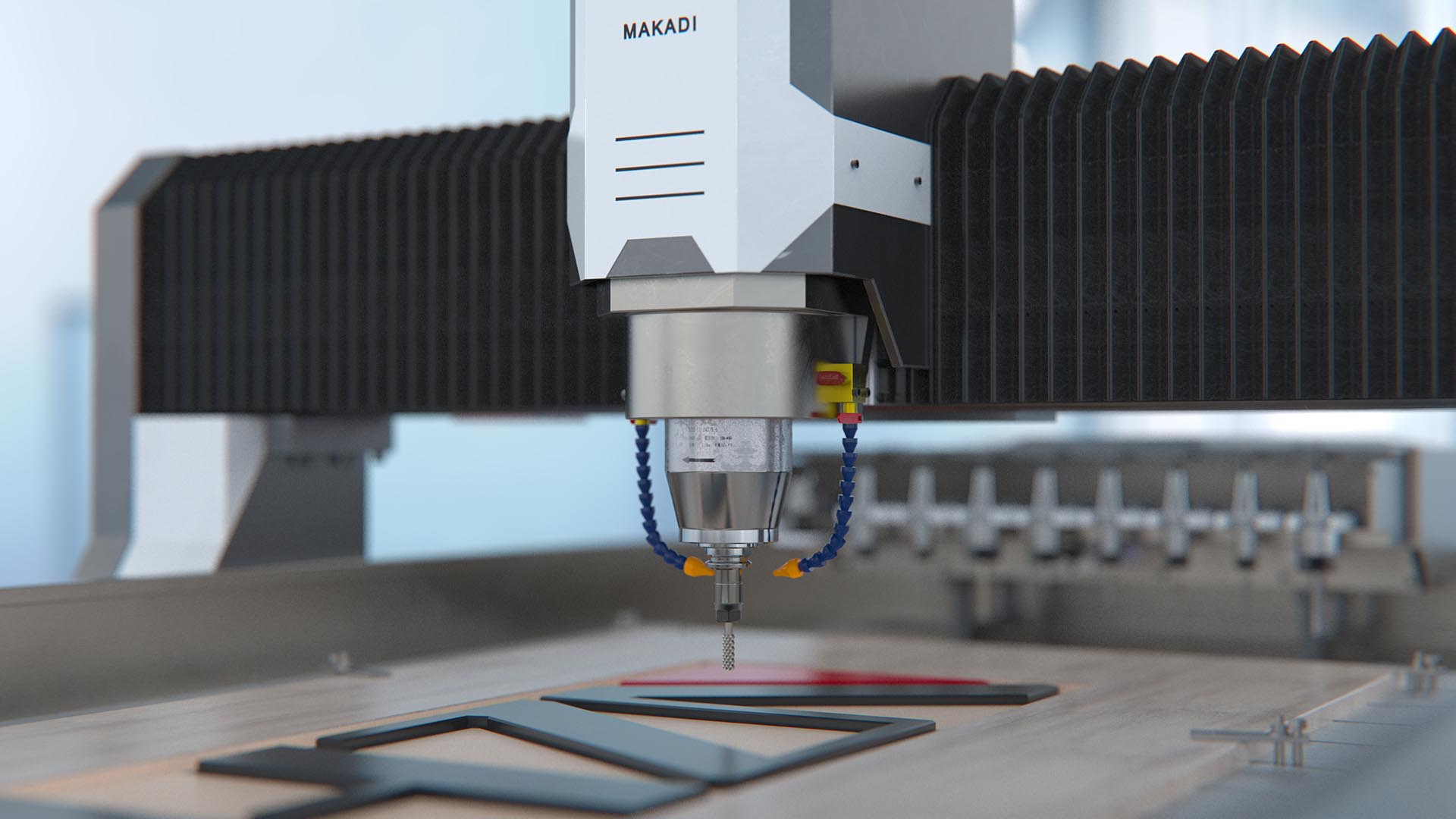

The Z axis is equipped with a holding brake device, the rack is also mostly selected 1.5 mesh, and the drive motors are also domestic hybrid servo, closed-loop pure servo or imported servo motor, which not only meets the standards of fast speed and high precision, but also meets the requirements of long-term processing and improves processing efficiency.

In addition, the spindleconfiguration of the two, the engraving machine is generally a low-power water-cooled spindle or a low-power air-cooled spindle, generally 1.5kw, 2.2kw, 3.2kw, etc.

In order to be able to cut plates at high speed, most of the cutting machines are equipped with high-power air-cooled spindles, common 4.5KW, 6KW, 9KW, 12KW and so on.

In terms of system, the

engraving machine is generally the Weihong board card control system or the handle control system of the four-axis machine, and many manufacturers are equipped with pirated cards, although the price is low, but it is also prone to some problems.

Cutting machines rarely use pirated systems, most of which are Shenzhen Shanlong, Shanghai Weihong, Taiwan Baoyuan or the new generation of intelligent panel control systems. This also makes the performance of the machine much more optimized than the engraving machine.

Then there is the difference in the use of software, the engraving machine is generally carving, Wentai, artcam, PM and other software to facilitate the realization of carving cutting relief hollow operation.

Because of thefunctional requirements, most of the cutting machines use some professional single-cutting software, such as Yunxi, Alpha, Xinxiaoyuan, 1010, Haixun and other professional cabinet door software.

It is easier to learn and operate, and the function implementation is more powerful.

The cutting machine uses supporting typesetting software to realize online design, presentation of 3D renderings, two-dimensional renderings, one-click unpacking, optimized typesetting, automatic hole arrangement and other functions. With vacuum adsorption table, the processing efficiency is greatly improved.

Moreover, installing different shapes of flower knives can not only realize all the functions of the engraving machine, but also do cabinet doors and wooden door shapes, compared with the engraving machine.

The above is the difference between the basic engraving machine and the CNC cutting machine, and the details of the two machines are also very different, if you are interested in understanding, you can leave a message for consultation.